Wrapper: Nicaraguan Corojo ‘99

Binder: Nicaraguan

Filler: Nicaraguan Corojo ‘99, Criollo ‘98, Medio Tiempo

Size: 5.625 x 52 Toro

Strength: Medium

Price: $16.00

My cigars have had 6 weeks of naked humidor time.

This is a limited release of 1000 boxes of 20. I do believe I’m jumping the gun here…hopefully, there will be no misfire.

BACKGROUND:

All AGANORSA tobacco.

From Atlantic Cigar:

“Originally released in 2018 as a 7 x 40 lancero, Moon Garden Especial gets upgraded to a 5 5/8 x 52 toro. And with the different size, comes a slightly different blend. Loaded with an all-Nicaraguan core, this iteration adds medio tiempo tobacco to the fold. Medio tiempo is the highest priming on a tobacco plant and thus the strongest. The potent blend is finished with a silky-smooth Nicaraguan Corojo wrapper and is ripe with flavors of earth, cedar, and generous portions of spice on the finish. Also balanced and smooth, Moon Garden Especial is a must-try for fans of Kyle Gellis’ cigars. Production is limited to just 1000 boxes, so get yours while you can!”

THE WHOLE MEGILLAH:

This is a good smelling cigar. Notes of caramel are upfront. Followed by creamy vanilla, ginger, jalapeno pepper, milk chocolate, sweet nuts, and cedar.

The draw is a tad tight but should open during early progression. If not, my PerfecDraw is standing at the ready. I tell it to sit down. It squats instead.

This is a big fucker of a cigar. If you smoke a lot of Gordos, it ain’t that big.

Creaminess gets your motor running. Worst part of being a Boomer musician…playing that damn “Born to be Wild” over and over till you want to puke.

Spiciness in the form of black and red pepper makes its debut.

Not a very complex start. It’s hard to know what is happening. Clearly a cigar this size needs humidor time. But with a time stamp on its availability, it is a roll of the dice to be able to make an educated guess on its viability as a good purchase. And it is $16 per stick. I’m telling you; this is where we are headed in 2024. I read some older reviews of cigars and every reviewer responded to a $10-$12 cigar as a very expensive and risky purchase. Times change. Next year at this time, we will be wishing that excellent cigars would cost only $10.

Spiciness and creaminess dominate the matrix. Or is that dominatrix? I get confused.

I believe that I won’t see the blender’s intent for a bit. The blend needs a warmup. A conundrum for a reviewer. Do I wait and review this cigar after it is gone…or do I jump in and try to make sense of the chaos. Or better yet not review it. Let it be.

I watched a 2022 live concert by Paul McCartney. His voice is gone. But I admire the man in that he is 80 and can deliver a 2-hour performance. It ain’t easy. Still, a time comes when you must revel in what you’ve accomplished and not embarrass yourself. I should take note of that advice.

1” burned. 30 minutes. A slow fucker.

A warmup is indeed required at this early juncture as it sorely needs additional humidor time. While Aganorsa tobacco is always good, I don’t believe there is any serious aging of this cigar. So, do I pack it in…or marshal on? Fuck me, onward Christian Soldiers. (I’ve forgotten to curse lately so I’m trying to get back up to speed).

The char line is remarkably lean. Construction is solid.

Richness is warming up in the bullpen. Complexity begins to simmer. I need a hot dog. I haven’t had a hot dog in ages. Only when watching a baseball game do those things taste good. Of course, a Chicago dog is always welcome.

Flavors are minimalistic.

Strength is medium.

I gander at the 19 Warped reviews I’ve done since 2015. I discover that my preferences lie in the smaller cigars that Gellis produced rather than the big hogs. My highest ratings were for Coronas or Corona Gordas. It could be me. But I think Warped does better when they stay in the small lane. Those petite blends have an intensity that the others didn’t possess.

Know what else I miss? French fries. That’s right. You want to be an old fucker? You have to stop eating crap…no matter how delicious it is. And here’s another conundrum…the further away you get from eating unhealthy foods, the worse they taste when you indulge yourself. Your brain detects toxins more easily. Bummer.

3” burned. 50 minutes. A really slow fucker.

Flavors have not really made their move.

Warped is allowed a misstep now and again.

Or…once again, this cigar needs an extensive sleep. But I’ve been smoking long enough that my brain would have recognized something special. This cigar ain’t special. It is only just OK.

The cigar limps home. It failed to hit it out of the park.

Sponsors Small Batch Cigar (10% off with promo code ‘katman), Luxury Cigar Club (15% off with promo code ‘katman’), and Atlantic Cigar have these cigars in stock. Cigar Page also has a nice selection of Warped blends.

RATING: 85

And now for something completely different:

I am dredging up this old story because the Milwaukee Brewers might get their asses waxed tonight by the Arizona Diamondbacks in the playoffs.

This story has nothing to do with rock ‘n’ roll or sex and drugs. It is a story about the building of the Arizona Diamondbacks stadium, starting in 1996 and finishing in 1998. It was called Bank One Ballpark. Now it’s Chase Field.

Of all the projects I participated in, this is my favorite. Seeing a baseball stadium built from excavation to sitting behind home plate and watching Mark McGwire smash a ball into the Jumbotron was pure delight.

Only nerds need apply for this story about structural engineering and what could have been a serious and deadly experience.

I was a senior project manager for a company that did high end metal fabrication and installation. Miscellaneous steel, rails, glass rail, stainless, bronze, copper, etc.

We had a huge contract to do all the foo-foo gingerbread stuff in the stadium. One of the many things we provided was a two-foot square panel, made of solid ¼” copper that was cut to show the Diamondbacks logo. It was cut using water jet technology. It is cleaner than laser cutting because it doesn’t leave burned edges. Laser cut edges must be ground smooth to remove the black burn marks. Obviously, water jet cutting is very, very expensive.

We provided hundreds of these panels, and they were inserted, every 8-10 feet, in all the guard rails in the stadium. They have since been removed because the idiot architects decided to pass on coating them in some sort of clear lacquer. This meant they wanted them to oxidize so the color would eventually look like an old penny. Which is not very pretty. Not to mention, people were touching them constantly. The oil from their hands left bright fingerprints and the whole thing looked horrible. After a couple of years, they removed them all.

I got the idea to make a 2” square version to use for key chains. I still have mine. I got enough for everyone at work but I had the shop coat them with lacquer so they would stay shiny. We paid $5 each for them.

Schuff Steel did the structural work on the stadium. And when they left, there was still a lot of miscellaneous metal work to be done, as extras or change orders, because the architects couldn’t find their asses with a gay metal detector.

The general contractor knew I had a structural background and gave us several million dollars in no-bid contracts to finish the stadium. Sort of a small Halliburton situation.

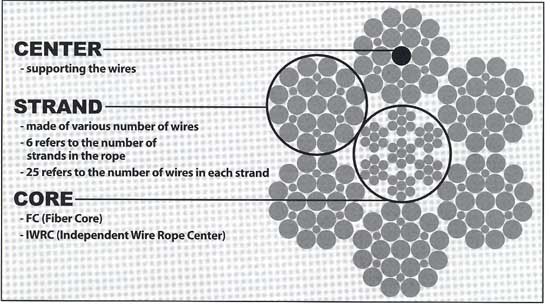

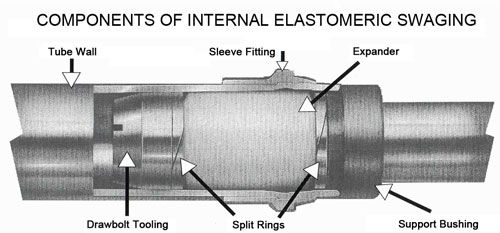

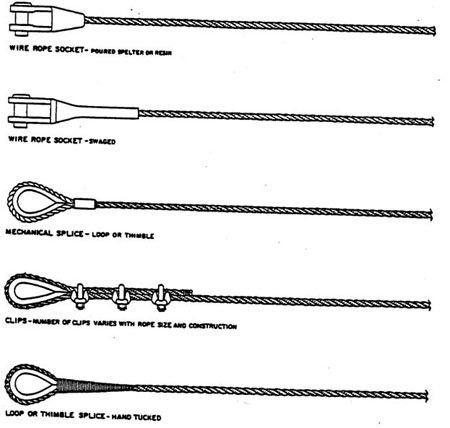

The back stop behind the home plate was a metal wire mesh panel and designed to protect people in those seats from errant foul balls. Believe it or not, the design was very complicated. The wire rope cable support was ¾” stainless steel. And the cables were attached using a swaged connection. This means the cable is inserted into a stainless-steel tube and then compressed, or crimped, to hold the cable in place. This was stupid considering the amount of tension/torque that would be placed on the units.

They should have used mechanical connections, which are basically tied off cable, but the dumb ass architects liked the clean look of the tube. This would backfire. And the stupid thing was that because the connections were so high, no one could see them anyway.

The main cable was over 800 feet long. It stretched from far-right outfield, down the first base line, around home plate, down the third base line, and then back out to left field by the bleachers.

I hired a contractor, that I had used before, that was out of San Diego. It took them over a month to install the cables. They had the cable connections fabricated by a company that did nothing but cable work.

Cables were everywhere. 20 cables were attached to the 800-foot cable to pull it back to create that parabolic shape. They had to tie these cables to the big swooping cable back to the second and third levels; thereby holding the big mutha’ in place. It required engineers to survey the installation so that as the cable was tightened in increments of 1/16″, the big cable would drop into place. One cable would be tightened to sixteenths of an inch, and then the surveyors would move to the next cable. They did this over and over in a certain sequence. Very complicated and I won’t bore you with the math. It took two weeks for the surveyors to get the cables tightened and at the right height.

I was there when they finished. Less than 30 minutes later, I looked up as I heard what sounded like a plane crashing into the stadium. The big right field cable connection came loose, and the cable was shot, like out of a cannon, all the way back to home plate along the first base line. It flew several hundred feet at the speed of sound.

Workers were everywhere in its path. There was over 30,000lbs per square inch tension on those cables, so when it came loose, it tore dozens of bolted seats and threw them 100 feet into the air… and sent them flying into the infield. Where the cable just barely touched the top of the seats, it left half circles of missing plastic at the top of the chair. It literally dissolved the plastic.

I watched as this loose snake missed hundreds of workers in its path. Had it hit one person, it could have decapitated him or cut him in half. And God help us if it happened during a game. It would have killed dozens of people.

So, you can imagine the brouhaha that followed.

The general contractor insisted that this time, the connections would be mechanical. Screw the architect. The blame for this was shifted to the manufacturer of the cable. In all situations, engineers over design connections, so that they are several times the required design. That’s how all structural steel is designed. The bottom line is that the manufacturer let this swaged connection pass inspection. Everyone asked where their quality control was. The GC demanded all their paperwork. It got ugly.

I spent the next two weeks supervising the re-installation of the cables. It was slow and laborious. It took four teams of surveyors and engineers to get it right. We had no liability, and it was not our fault. But we were the messengers, so to speak. And the GC was really pissed off at us for something that was not our fault. The cable company took full responsibility for this and re-fabricated the connections at their cost. And they had to pay for the re-installation…and the four teams of surveyors.

I remember standing in the rain, due to a leaking retractable roof, in the middle of February. The closing roof had so many leaks that it was like a rain forest inside the stadium. And I got sick as a dog the first week. After seeing how diligent I was, the GC got off my back and our relationship went back to normal as they came to terms with it made no sense to hold me personally responsible.

As expected, the owner of the company I worked for didn’t give a shit if I was sick or not. I was to be there every single day until it was fixed…10-12 hours, 6 days per week. I remember taking the cable connection part that failed and having it made into a coffee table curio. I had the connection welded to a stainless-steel plate.

When re-installation of the cable was complete, I spent the next four days in the hospital with pneumonia. The boss never visited me once. He was a raging asshole.

The only upside was that I spent almost two years watching a ballpark being built. From breaking ground in 1996 to the laying of the sod in 1998. Once the sod was down, they put guards around the playing field to make sure no workers stepped on the grass.

Later, when the park was open, I went to a game with our CFO, and we had home plate seats. I got there early because the D-backs were playing the Cardinals. And I wanted to watch batting practice.

I remember being in awe at the size of Mark McGwire when he came to the plate. I was only 30 feet away. And I watched as he hit every pitch outside the park. And his last one smashed a hole in the Jumbo-Tron.

The D-Backs lost the game that day.

Categories: CIGAR REVIEWS

You must be logged in to post a comment.